A dedicated team, comprising of a number of trained quality engineers, makes sure that all the required quality needs of the customer are taken care of, by way of dimensional checks, surface finish, machined accuracy, drilled and tapped dimensional checks, RA value checks, regular in process gauging and dimensional checks, supported by Cp & CpK inspection methodology .

We further undertake the manufacture of special purpose gauges for the various stages of production activity so that quality can be maintained even at the grass root level of the worker.

Checking by way of Optical measurement devices like CMM or Trimoss are also undertaken by us for high accuracies and difficult measuring surfaces.

We have a fully equipped and ultra modern Test Laboratory and facility for testing the powder coated parts as per ASTM standards. This in house lab regulates and assists our production team to get some industry leading quality for our powder coated parts.

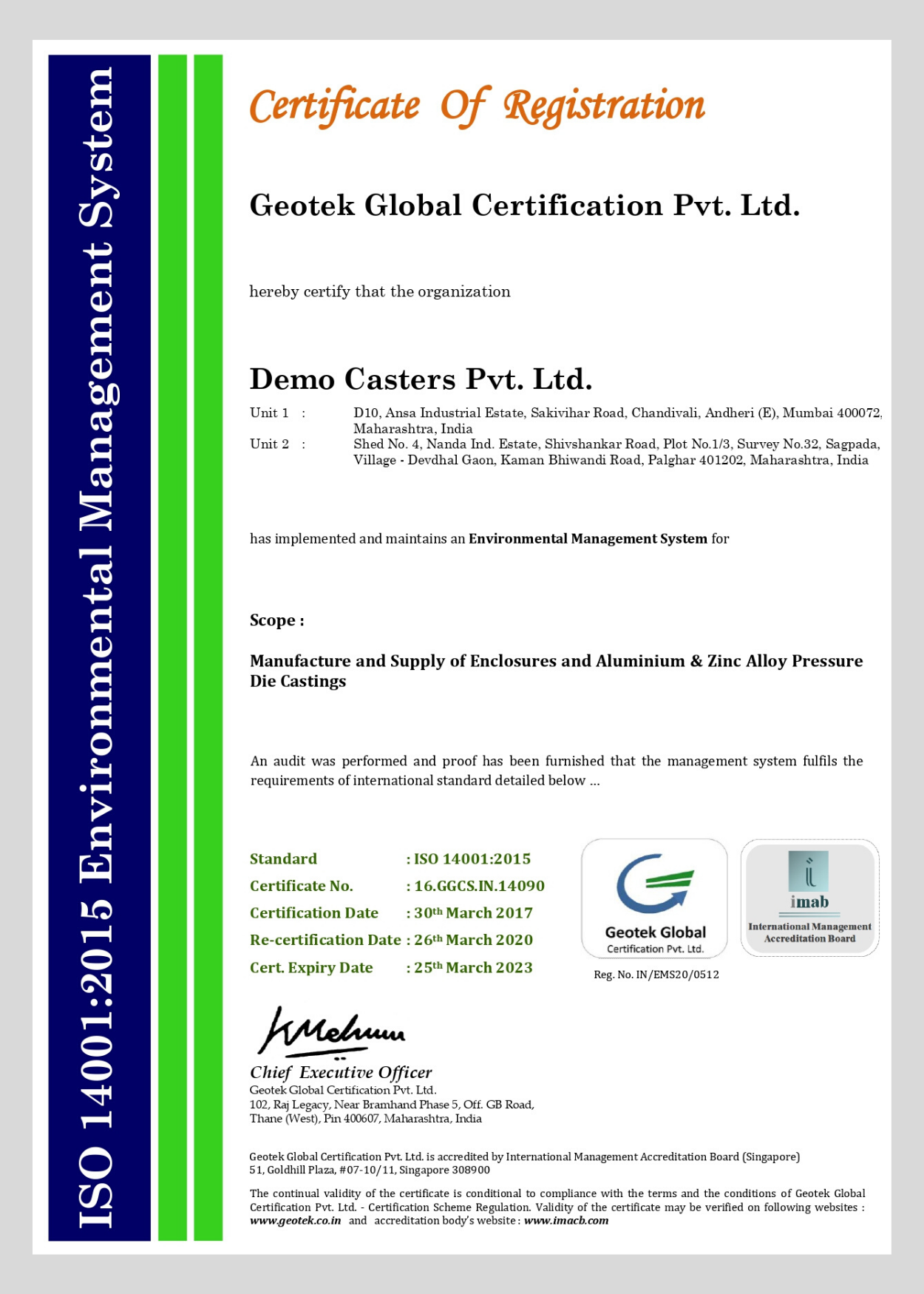

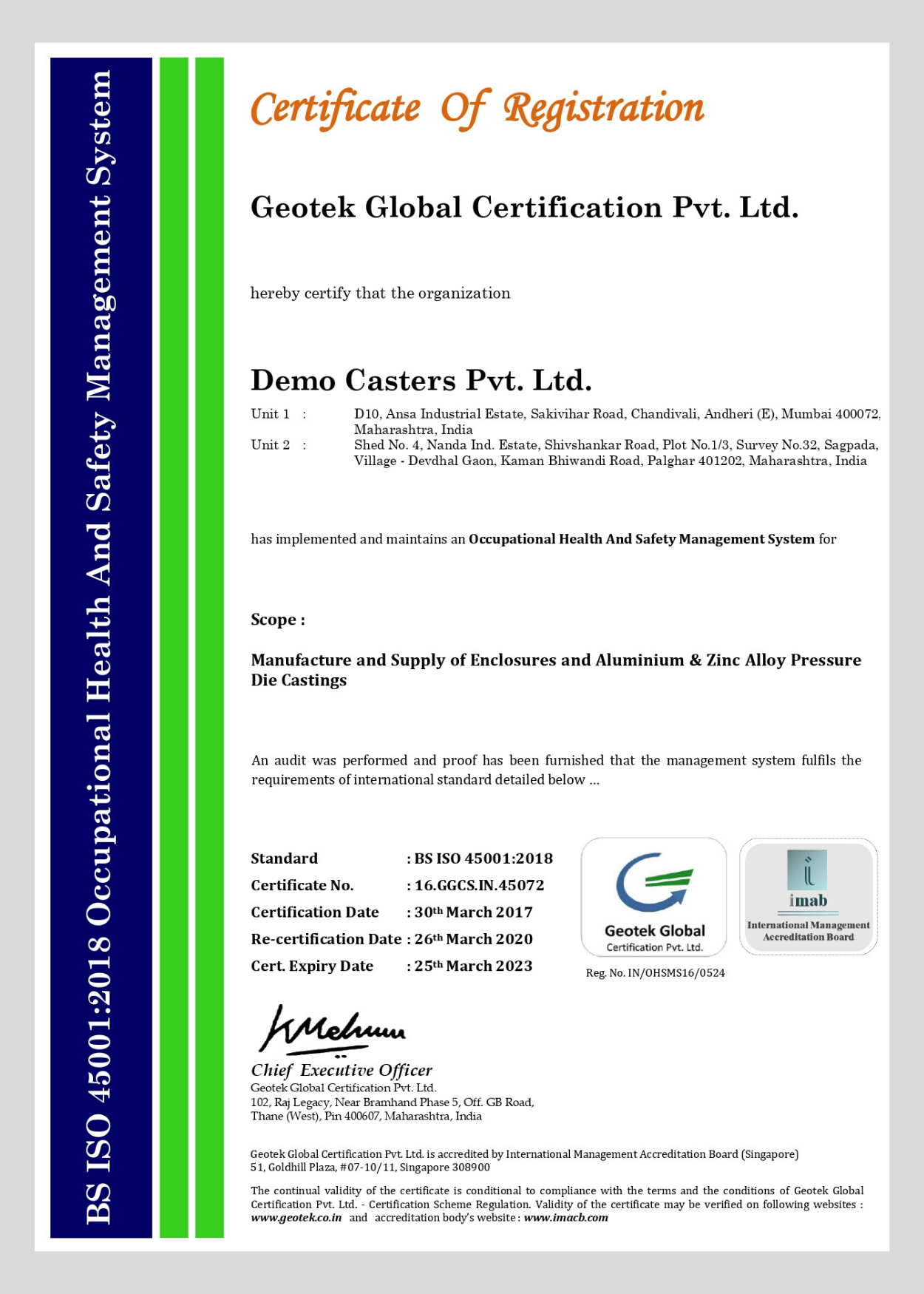

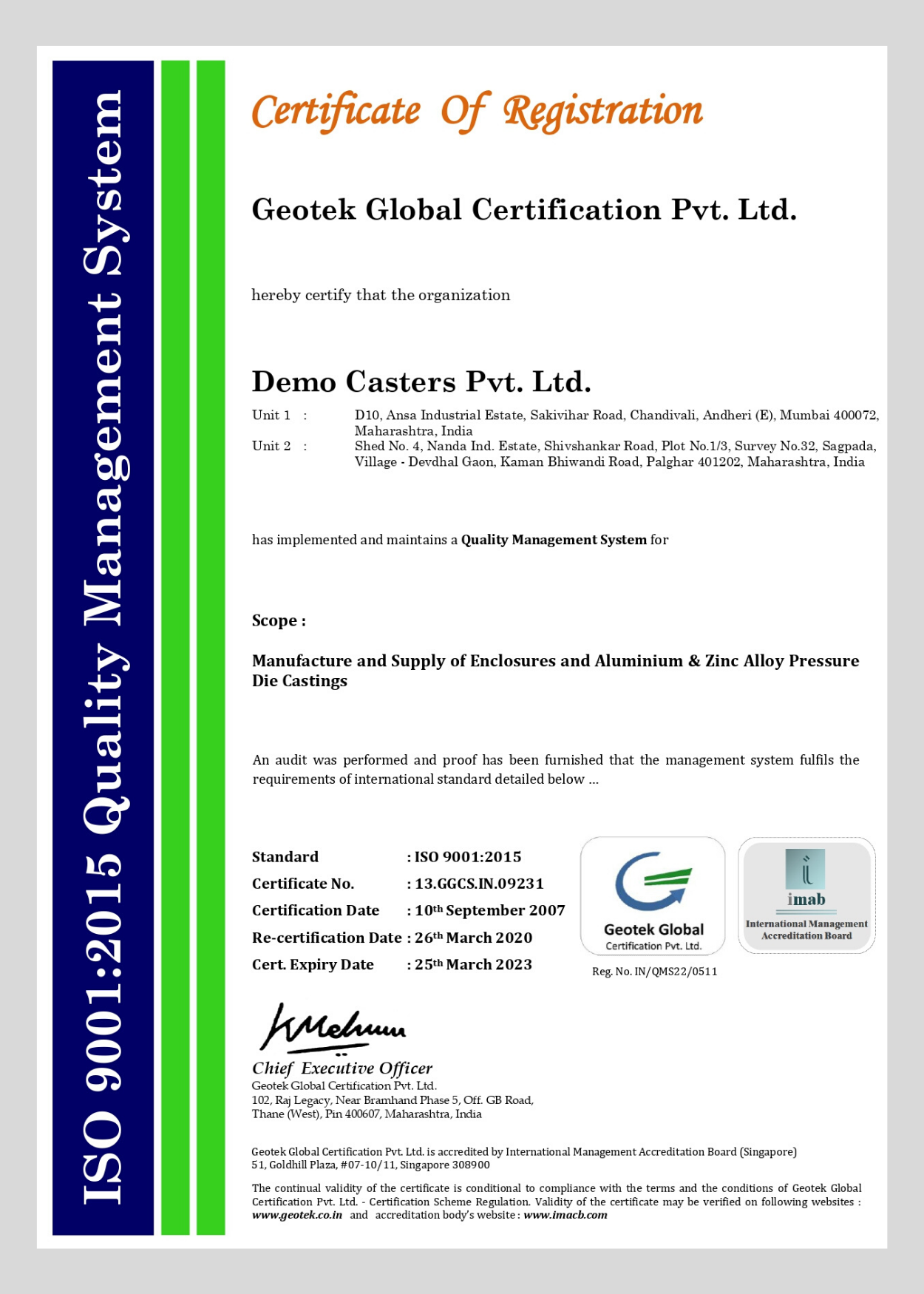

We follow and comply with the Quality Management System as per DIN EN ISO 9001:2015, Environmental Management System DIN EN ISO 14001:2015 and Occupational Health and Safety Management System BS OHSAS 18001:2007.

Recent Comments